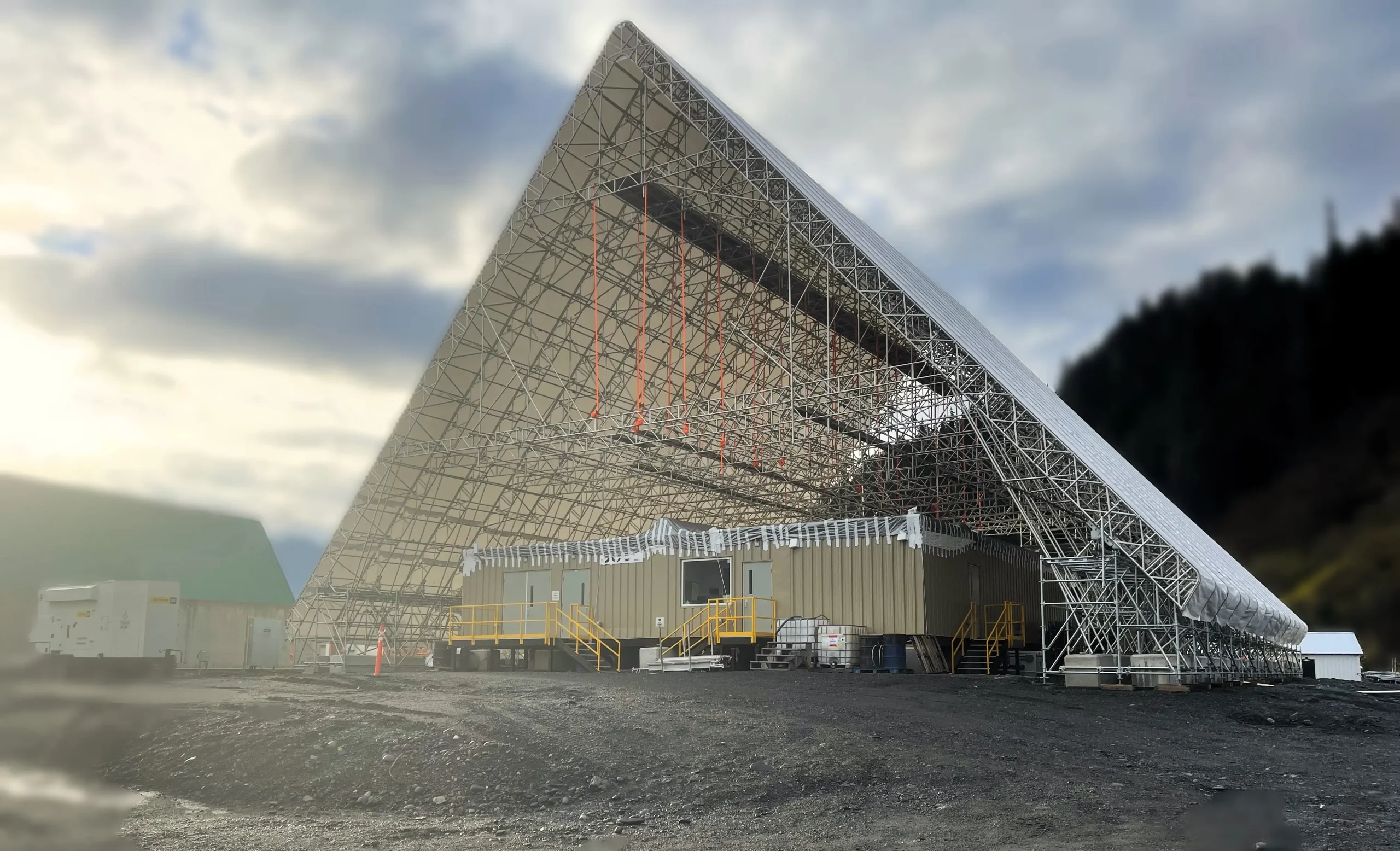

Industrial Roof — Compressor Station Coastal GasLink project

This project included the equipment to construct an on-site operations lab enclosure utilizing NSP’s innovative Diamond Beam Roof System. This advanced custom enclosure was designed to shield the lab from severe weather conditions, ensuring the safety and integrity of critical research operations. The Diamond Beam Roof System’s unique features guarantee superior strength, stability, and weather resistance, providing a reliable defense against extreme elements such as heavy rain, strong winds, and intense snowfall. Our objective is to create a secure environment that allows uninterrupted on-site work, enabling the lab to function optimally regardless of external climatic challenges.